Siemens gets Iran’s major compressor order

Iran’s Hampa Engineering Corporation says it has put a major order with Siemens for 12 compressor trains for two onshore natural gas processing plants.

The order volume is in the “high double-digit million euro range,” with commercial operation expected by the end of 2018, the Iranian company said.

Siemens Iran CEO Mohsen Nayebzadeh called it the first huge oil and gas order since the easing of sanctions on Iran in January 2016.

Under the contract, the German engineering group will supply compressor trains each comprising a Siemens STC-SV vertical split compressor that will be used in two natural gas processing plants in Iran.

Of the 12 trains, ten will be used for the Mohr C2+ hydrocarbon recovery plant, located in Fars Province in south-central Iran. The plant is designed to process natural gas into C2+ hydrocarbons.

The order also calls for the supply of two other compressor trains for a hydrocarbon recovery plant in Asaluyeh where Iran’s biggest gas projects are located. The plant will produce important feedstock for the petrochemical industry, including ethane, propane, and butane.

“With Siemens, we are assured of proven technology for our project,” Managing Director of Hampa Engineering Corp. Hamid Elyas said.

“Siemens is a partner that has all the capabilities necessary to execute such a huge scope of supply, such as the 12 compressor trains for the C2 recovery and fractionation project,” he added.

Four of the STC-SV compressors for the Mohr plant will be driven by SGT-700 gas turbines and four more by SGT-100 gas turbines. Two others will be driven by an electric motor, according to Siemens. Another two compressor trains in Asaluyeh will each be driven by a SST-600 steam turbine.

Part of the hydrocarbons produced in Mohr will serve the domestic Iranian gas market, while the long-chained hydrocarbons will be transported in a pipeline to the Iranian coast 60 km away. The hydrocarbons will be further fractionated at the Asaluyeh plant in Bushehr Province.

“Our best-in-class technology and our reliable expertise in the Iranian oil and gas business will help the Iranian people develop a sustainable, affordable, and modern electrification system,” Nayebzadeh said.

The German company’s activities in Iran go back as far as 1868 and involve important infrastructure projects.

Siemens was one of the first major companies to agree on a deal with Iran after the lifting of sanctions, signing a $1.6 billion MoU on Iran’s rail infrastructure and a long-term roadmap with MAPNA on the power sector.

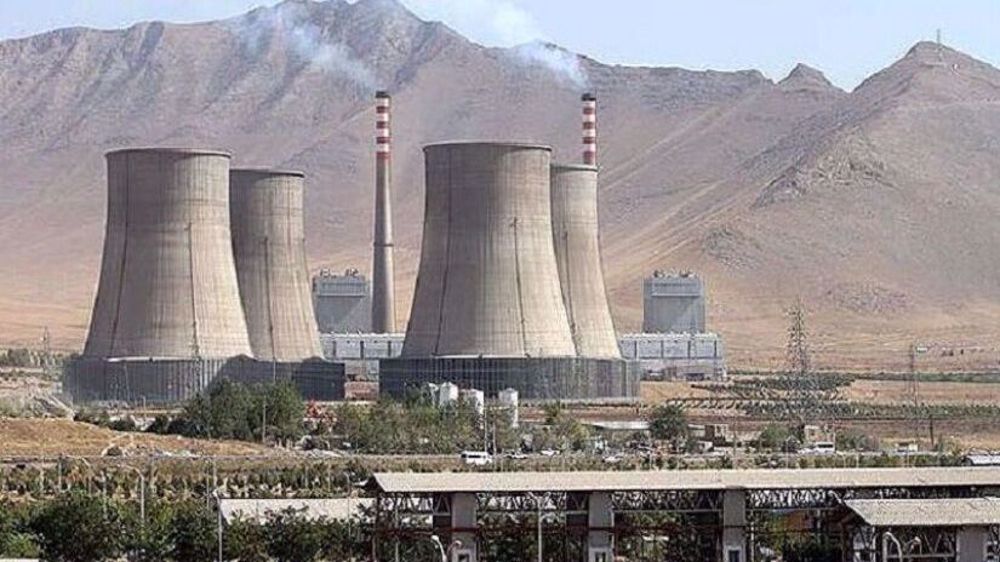

The group shipped the first F-class gas turbine to Iran for the construction of a 600-megawatt power station in Bandar Abbas on the Persian Gulf last September.

It was one of the two gas turbines which Siemens would supply to MAPNA, an Iranian energy and infrastructure conglomerate, along with two generators and the associated power plant instrumentation and controls.

After the lifting of sanctions on Iran, Siemens signed a far-reaching agreement with MAPNA to collaborate on the transfer of know-how for the F-class gas turbine technology to modernize the Iranian power supply system.

‘All wars have rules. All of those rules have been broken’ by Israel

VIDEO | Report flags India’s violation of rights of Rohingya detainees

Turkey's foreign minister meets Syria's de facto leader in Damascus

'Next to impossible' to rescue patients from Gaza's Kamal Adwan Hospital: Director

VIDEO | Vietnam current prosperity

Report blames gasoil exports for shortage at Iranian power plants

VIDEO | Hind Rajab Foundation names Israeli war criminals vacationing after Gaza genocide

VIDEO | Australians rally for Gaza ahead of Christmas festivities

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website