Uma Oya: Iran’s engineering milestone for internationality

The ability and scientific skills of Iran's specialists, professors and academics have made it stand out as one of the countries with a capacity to export technical and engineering services in the recent decades.

According to the statistics of the Commercial Services Development Office, the export capacity of Iran's technical and engineering services is more than $20 billion a year, and Iranian specialists and engineers can contribute to the prosperity of economic enterprises and expert human resources by participating in prestigious international projects.

The participation of companies supplying technical and engineering services in Iraq, Syria, Latin America and many other countries is a clear example of the growth of Iran's technical and engineering services exports in recent years.

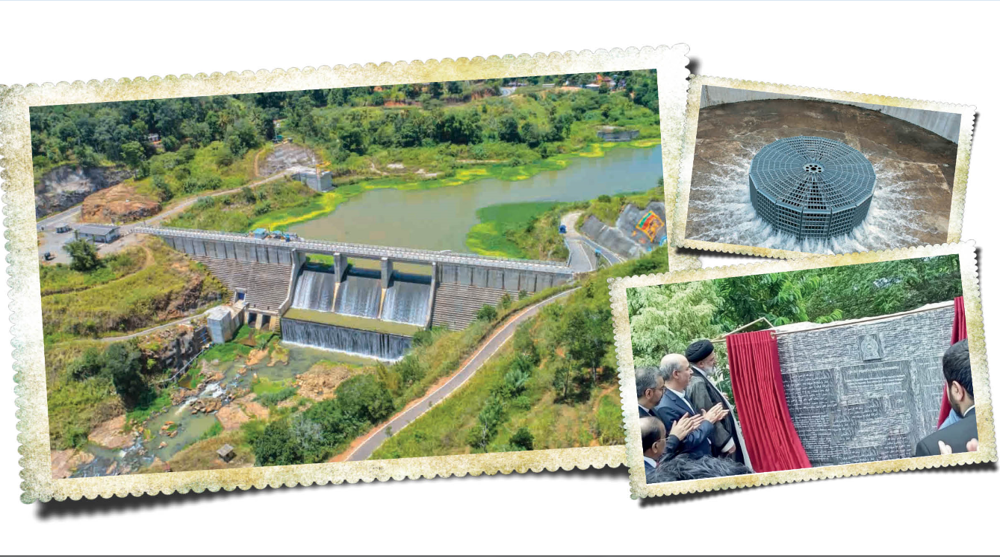

Inaugurating a hydropower and irrigation project in Sri Lanka last week, President Ebrahim Raeisi said Iran has proven the West doesn’t have a monopoly on technology.

In 2010, Sri Lanka’s ministry of irrigation signed a contract worth $529 million with Iran’s Farab company as the main contractor to design and construct two concrete roller dams, a water transfer tunnel and a 120 MW power plant in the country.

The project was launched the same year in southeast of Sri Lanka, 200 km from capital Colombo on the Uma Oya river.

The contract required that Iranian engineers build a dam on Uma Oya in the Puhulpola region and transfer the water through a 3.7-km long tunnel to another dam which they should build on the Malwathu Oya river.

They should then build a 15.2-km long headrace tunnel and a 595-meter vertical shaft to transfer the water to an underground power plant from which the water would be directed via a 3.6-km tunnel to the Alikuta Oya river.

The goal was to improve the irrigation of 5,000 hectares of agricultural land, transfer 145 million cubic meters of water per year and produce 290 gigawatt hours of energy per year in Sri Lanka.

The technical dimensions of the project included pipes with a diameter of 2.2 meters and a well with a depth of 680 meters. The pipes had to be welded together in 9-meter pieces and installed along the entire length of the tunnel and finally poured concrete around them.

A 20-people team was responsible for the implementation of the project. The design work lasted eight months and the manufacturing of the parts took about four months to complete in two main workshops.

All the equipment was made in Iran and then transferred to Sri Lanka. But the most important part of the project was the design, construction and installation of the vertical shaft, which was carried out by Mohammad Durali, a professor of mechanics at Sharif University of Technology, and a team of Iranian students and engineers.

In total, 150 foreign and 50 Iranian companies helped Farab in carrying out the project. Austria’s Andritz, Germany’s Herrenknecht and Switzerland’s Marti were the most important foreign companies in the implementation of the project.

Also, the Mahab Ghodss Consulting Engineering Company, Shahran Sazeh, Ev-Yol, Parhoon Tarh, Kerman Tablo, Elektrokavir Yazd and Tana Energy were the most important Iranian companies that cooperated with Farab.

According to Project Manager Pashutan Ahmad Dezfouli, the Uma Oya water transfer tunnel is one of the few in the world with no intermediate access for its mapping. The excavation of the irrigation tunnel was done by two tunnel boring machines (TBMs), better known as moles, one in the entrance and the other in the exit section.

The design and construction of the vertical shaft used in the project was the largest built for the first time in Iran in a completely modern way.

"The robotic set, one of the key and very crucial parts of the project, was completely designed and manufactured in Iran and sent to Sri Lanka. The installation of the vertical shaft in the Uma Oya project was also done in less than a quarter of the time of common methods,” Prof. Durali says.

Shafts are the doorways to the underground tunnel, serving as the location at which all material enters and exits. They vary in size and depth, and their design and construction are key to the successful completion of any tunneling project.

In civil engineering, they are constructed for a number of reasons including the construction of a tunnel, ventilation of a tunnel or underground structure, as a drop shaft for a sewerage or water tunnel or for access to a tunnel or underground structure.

“Iran does not lack anything in terms of hardware to meet its current and future needs, and in terms of technical knowledge and software development, it is completely up-to-date at the level of the country's pressing needs,” Prof. Durali says.

“The only weak link is the low risk appetite of some of the country's decision-making managers, who in most cases are the main obstacle to doing great things. Also, the absolutist view and acceptance of solutions offered from abroad is the main obstacle to the development of engineering capabilities and the use of internal forces.”

VIDEO | Gazans search rubble for survivors after Israeli strikes on Jabalia

VIDEO | Nakba Day anniversary

VIDEO | Interview with Sandrew Hira

Hezbollah retaliates heavily against Israel after cmdr. assassination

VIDEO | Victims of 2017 Zahedan terrorist attack say US sponsors terrorism in region

VIDEO | Palestinians mark anniversary of Nakba in shadow of Gaza war

Hamas marks Nakba Day, says Israel failed to achieve goals in Gaza

VIDEO | Nakba Day: Gaza solidarity and a call for American universities to divest from Israeli companies

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website